At Drug Plastics, we manufacture many types of plastic closures for our bottles: Continuous Thread, Snap Cap, Dispensing Top, as well as a variety of Push and Turn Child Resistant Closures (CRC), like our SecuRx Closures. Different types of products require different types of closures. For example, many products require the use of a Child Resistant Closure (CRC). When a CRC is selected for a product, it’s vital that the closure and bottle are dimensionally aligned.

Hundreds of plastic bottles in all shapes and sizes can be paired with a Push and Turn CRC. It is important to recognize the dimensions which are critical to the secure functioning of the child resistant closure. However, keep in mind that not all closures are designed with the same geometry as a CRC, and selecting the incorrect closure can keep the seal from being secure, or negatively affect the child resistance function. There are factors that can inhibit the seal from being secure, and keep the bottle and closure from working together. The critical dimensions of a Push and Turn Closure are vital to ensure that the package has a proper seal.

Understanding the Components

Understanding the critical dimensions of a bottle will help determine the best bottle and closure combination for a product. Let’s begin by defining the parts of a plastic bottle that can affect proper sealing.

- Land Area: the lip portion of the finish that makes direct contact with the inside of the closure, sealing gasket, or liner to form a seal.

- Transfer Bead: the pronounced ring of plastic beneath the neck area at the foot of the finish used during the molding process. The transfer bead can be modified to provide tamper evidence on a package.

- Shoulder Area: the transition between the base of the neck and the body of the bottle, generally the widest portion of the bottle.

- Bottle Neck: in simple terms, the neck is the part of the bottle that contains the opening. The neck is where the shoulder of the bottle transitions to form the finish.

- Finish: the part of the bottle that accepts the closure.

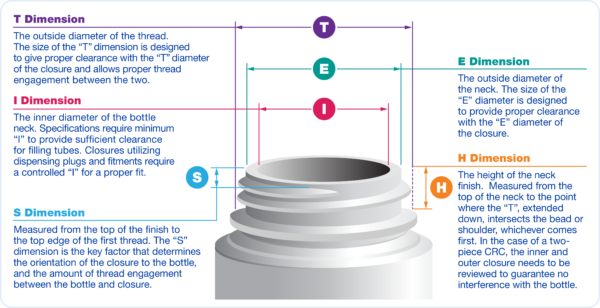

The diagram below shows the neck dimensions and the definitions of each measurement that form the finish of a plastic bottle.

Each dimension must be precise, and meet specific industry standards in order to provide child resistance and a proper seal with a Push and Turn CRC. Meeting the standards is imperative to keep the contents secure and child resistant. Our SecuRx closures meet all industry standards for safety.

Why a Push and Turn CRC May Not Fit

Let’s review the most common reasons a Push and Turn CRC may not work with a particular bottle:

- The E diameter of the bottle neck is not sized in the proper relation to the closure.

- The T diameter of the bottle is not sized in the proper relation of the size of the closure.

- The H dimension of the bottle is too short in relation to the H of the closure and liner combination. A review must be completed to ensure that the inner and outer portions of the closure do not interfere with any portion of the bottle before it makes full contact with the land area.

- An incorrect S dimension can result in an incorrect number of threads engaged between the bottle and the closure, potentially resulting in an incomplete seal.

- The I diameter is not sized properly to give the correct amount of land surface required to adequately seal to the closure liner.

- The thread geometry of the bottle is not designed to work with the thread geometry of the closure.

- The thread pitch of the closure does not match that of the bottle.

There are other reasons too. Navigating all the different scenarios can be overwhelming. And, gaining all the knowledge needed to design product packaging is certainly time-consuming. Do you work with a manufacturer that provides all of the necessary information?

A Trusted Packaging Partner

That’s where we can help. Our team of experts can review your application and determine if your bottle will work with a SecuRx closure. If not, we will recommend one from our vast inventory of stock bottles that can be used with a SecuRx closure. We will help you navigate regulatory requirements for child safety and help ensure your products are secure. At Drug Plastics, we have over 60 years of experience designing bottles and closures that work together to protect medications, vitamins, supplements, and lifestyle products for consumers.

When you work with us, you have a trusted partner to help determine what packaging is right for your product. Call 610-367-5000 to speak with a knowledgeable team member today.