Our History

The Founding

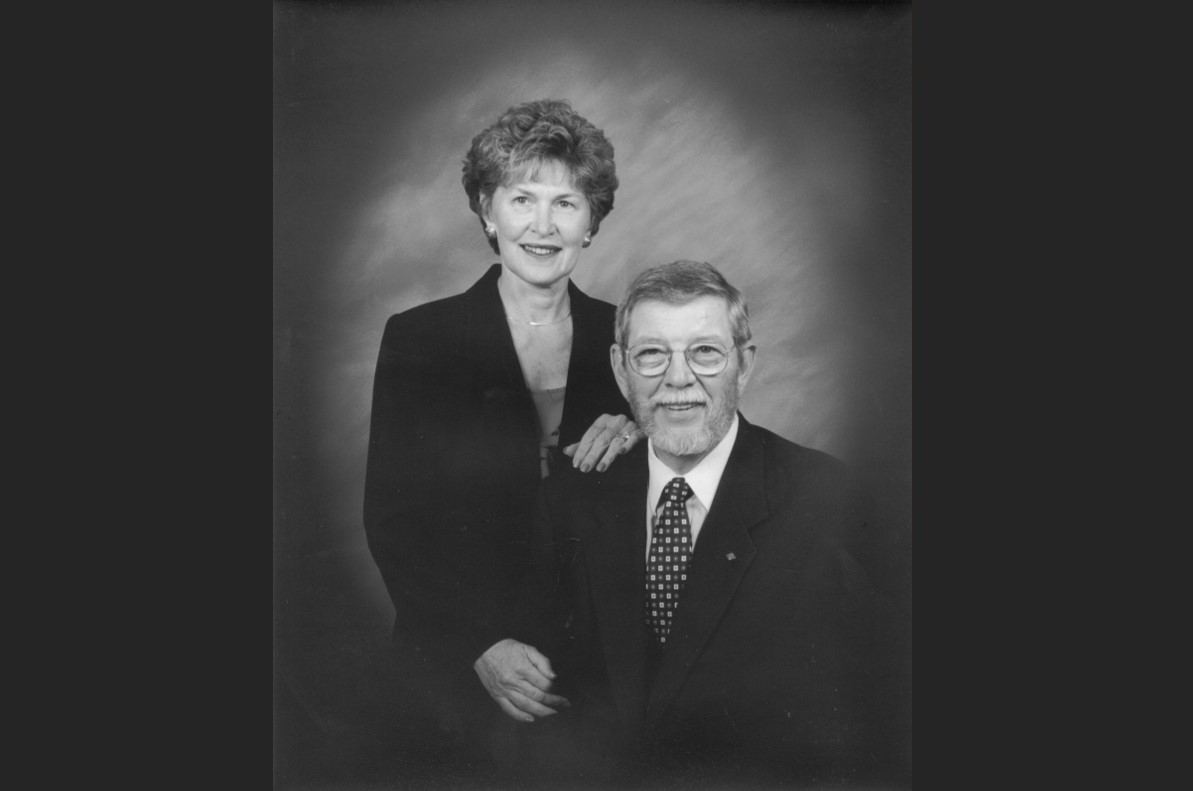

In 1963, Fred N. Biesecker and his wife, Suzanne Kohler Biesecker, began their entrepreneurial journey with a small sole proprietorship selling plastic prescription bottles and glass containers to drugstores.

Through determination, hard work, and dedication to customers, they laid the foundation for a business that would eventually grow into a worldwide corporation with over 800 employees and eight plant locations across the United States. Currently, Drug Plastics manufactures plastic bottles and closures for pharmaceutical, nutraceutical, and lifestyle industries around the globe.

The Early Years

It was a humble beginning with operations and warehousing conducted in the basement of their home in Boyertown, PA. Fred and Suzanne differentiated their wholesale business by having the plastic vials made from injection molds they purchased, ensuring a guaranteed supply source for their growing customer base.

In 1967, Drug Plastics purchased the Prescriptionware Division of Ball Brothers Company of Muncy, IN allowing for the expansion of the product offering to include glass bottles and vials. The Baby Bottle Division of Hygeia Corporation of Baltimore, MD was also purchased. The popular Hygeia Nurser became part of the growing product offering.

Manufacturing Begins

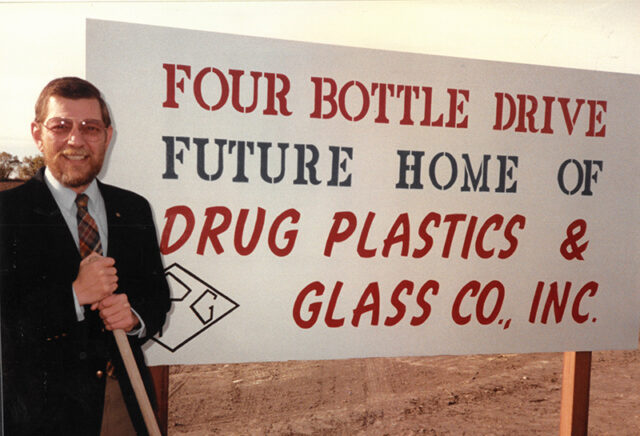

Shortly thereafter, Drug Plastics purchased Delaware Valley Molded Products in Reading, PA. When a new manufacturing facility and corporate headquarters was built in Boyertown, the equipment from the Reading plant was moved.

The first plastic bottle was blow molded at the Boyertown plant on April 19, 1971. In addition to servicing pharmacies, the company began manufacturing bottles for the cosmetic, personal care, chemical, novelty, and food and beverage industries.

Additional Bottle Plants

In 1977, the company built a second manufacturing facility in Kittanning, PA after multiple expansions to the Boyertown plant. Drug Plastics saw an opportunity in the pharmaceutical and nutraceutical industries. It began building a product line to deliver high quality packaging for prescription, over-the-counter medications, and nutritional products. The Spartanburg, SC manufacturing site was built in 1981 to address increasing customer demand.

In 1983, Drug Plastics opened a mold fabrication facility on the Boyertown campus to manufacture new molds and maintain existing molds for its customers. By 1998, Drug Plastics built three more bottle plants in Valley City, ND, Oxford, IN, and Elysburg, PA, bringing the total number of manufacturing sites to six.

Closure Manufacturing Plants

In response to customer demand for complete packaging systems, Drug Plastics acquired Top Seal Corporation in 2001. The exclusive SecuRx® Child Resistant Closure line from Top Seal offered exceptional child resistance and complimented the Drug Plastics line of bottles.

In 2007, Top Seal became Drug Plastics Closures with manufacturing sites in Phoenix, AZ and Edinburgh, IN.

Drug Plastics Today

Drug Plastics is the premium packaging manufacturer for healthcare, wellness, and lifestyle brands that desire perfect bottles and closures.

Today, Suzanne Biesecker, is Chairman of the Board. Rick Biesecker, CEO, and Lissa Biesecker Longacre, President, currently lead the Drug Plastics Executive Team.

Continuing Our Story

The world faced a global pandemic in 2020. Under these conditions, Drug Plastics is considered an essential business. We instituted our “Humanity First” program, where bottle and closure orders for companies that make life-saving medications were pushed to the front of our production lines.

Drug Plastics is committed to reducing its carbon footprint and takes steps to conserve natural resources for future generations. The company expands the ways it can reduce greenhouse gasses in the plastic bottle and closure manufacturing process.

The communities in which Drug Plastics operates are important to its success. The company takes the initiative to support local events where our employees volunteer their time and talent for the greater good. We believe that building communities, supporting local economies, and sponsoring local organizations is just the right thing to do.