Choose Plastic over Glass for Better Sustainability and Lower Costs

When choosing product packaging, companies have many material choices like glass and various plastics. Both glass and plastic containers are available in many standard sizes and shapes, and both can be customized to a specific brands’ needs. Because of increasing consumer awareness about sustainability and climate change, companies worldwide are making an effort to reduce their carbon footprint and leave a more positive impact on the planet. An important way companies can realize improved sustainable impact is through better product packaging practices. If sustainability is important to your business, plastic offers significant advantages over glass:

- Raw material sustainability

- Environmental impact from the manufacturing process

- Energy required to transport

Similarly, companies are continually looking to manage costs associated with their products. Plastic packaging excels in cost savings compared to glass. Companies can improve their bottom line by switching to plastic and realize cost savings in these key areas:

- Production

- Shipping and handling

- Transportation

Sustainable Benefits of Plastic

Here are the details on how plastic packaging offers greater sustainability over glass packaging. Continue reading or watch our video to learn more.

Raw Material Sustainability

Sand is the primary ingredient in glass. During the glass manufacturing process, sand melts at an extremely high temperature into a liquid state, and then is molded into bottles. Although it may seem like we have a readily accessible and abundant supply of sand, it is actually used faster than it is naturally replenished. In addition, high silica sand is required to make glass. Sand with a high silica content is typically found in active or extinct riverbeds and sea beds. Removing this sand can have far-reaching consequences.

Displacement of sand negatively affects many ecosystems. Sand removal can cause damage to surrounding habitats, disturb river flows, and cause lasting harm. In addition, removing sand from the sea bed also leaves shore communities prone to flooding and erosion. For these reasons, sand consumption is not the most sustainable or environmentally sound practice.

Like glass, plastic production relies on finite natural resources; however, compared to glass’ constant drain on raw materials, plastic offers unique benefits in recycled applications. Most plastics are petroleum-based – made from oil and natural gas. Drilling for oil disturbs both the land and marine ecosystems. Oil spills sometimes occur, contaminating soil and water. Oil and natural gas may cause catastrophes such as fires and explosions. However, there is an alternative sustainable plastic resin available through Advanced Recycling.

Advanced Recycling of Plastics

Advanced Recycling is a game-changing process for sustainable packaging. Post-consumer waste and several other feedstock sources are used to generate identical ethylene molecules to create new batches of virgin resin.

Advanced Recycling is the emerging sustainable method to obtain ethylene molecules through transforming post-consumer waste into a pyrolysis oil feedstock. Advanced Recycling creates a Circular Economy.

Environmental Impact from the Manufacturing Process

Producing glass is an extremely heat-intensive process and uses a large amount of energy. A furnace heats the raw materials to 2600-2800° F for melting. The temperature is reduced as the molten glass is cut, molded, and blown into its final bottle form. The glass making process requires energy that is equivalent to 3.0 grams of CO2 per 1.0 gram of glass.

On the other hand, producing plastic utilizes less energy. A reactor polymerizes the hydrocarbon raw materials into resin pellets. Then the resin ships to a processor. Using temperatures of 400-500° F, the processor melts the resin, and then blows it into a mold forming the bottle. The energy used to make and process plastic is equivalent to 3.8 grams of CO2 per 1.0 gram of plastic.

In addition, more material is required to make glass bottles. For example, an 82.2-gram glass jar at 3.0 CO2 equivalents per gram has a total impact of 246.6 grams of CO2 equivalents per jar. A lighter 13.0-gram HDPE plastic jar with 3.8 CO2 equivalents per gram has a total impact of 49.4 grams of CO2 equivalents. The plastic jar has only 20% of the carbon impact of the glass jar. It would take five plastic jars to equal the environmental impact of just one glass jar. This demonstrates the full story when comparing the energy need to make glass versus plastic.

Plastic has a clear advantage.

The CO2 savings is significant with plastic. Use the example of an order of 1,000,000 2 oz. jars. In this scenario, glass jars yield 246.6 metric tons of CO2, but plastic jars only yield 49.4 metric tons of CO2.

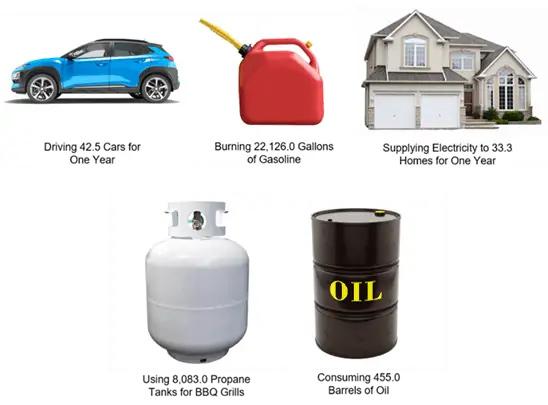

This yields a savings of 197.2 metric tons of CO2 when using plastic. The savings is equivalent to these everyday items:

Energy Required to Transport

Because glass is very fragile, it requires extra packaging during transport. Extra packaging takes up more space on a trailer. Conversely, plastic bottles use less packaging and take up less space on a trailer, resulting in more plastic bottles and less packaging on the trailer. It takes more fuel to transport glass products the same distance as plastic products because glass is heavier. Using more fuel means greater carbon emissions. Transporting glass bottles yields a greater negative impact on the environment.

Cost Benefits of Plastic

Here are the details on how plastic offers greater cost savings. Continue reading or watch the video to learn more.

Plastic Reduces Production Costs

Right from the start, plastic has a cost advantage over glass: plastic is less expensive to produce. The manufacturing processes for both plastic and glass packaging are quite similar, as both involve heating raw materials and then using molds to give it the desired shape and thickness. The amount of energy required to manufacture plastic bottles differs from the amount required for glass manufacturing.

Depending on its specifications, glass melts at between 1400-1600° C. Meanwhile, plastic melts at a much lower temperature – around 170° C. This means plastic requires significantly less energy to shape and manufacture. Further, advancements in molding technologies continue to lower plastic production costs, as bottles can be shaped using less heat and more quickly, requiring even less energy. Taken as a whole, plastic production is a more efficient process than producing glass.

Plastic Reduces Shipping and Handling Loss

Shipping is a complex, time consuming, and expensive process. Many activities occur throughout the shipping process:

- Empty bottles are shipped to the filling location

- Bottles are filled

- Bottles are then distributed to final locations

This multi-stage process leaves room for product loss. The more often glass bottles are handled, (whether during the shipping or filling process), the higher the potential for damage to occur. Glass can easily shatter. This poses a safety concern to employees, and means a cut into your bottom line.

Shaking and bumping are common during the shipping process, leaving glass vulnerable to chipping, cracking, and shattering. On the other hand, plastic is more durable and resists cracking and breakage.

Plastic Reduces Transportation Costs

Glass is comparatively heavier than plastic. Consider the following measurements: glass has a density of approximately 2.6 g/cm3 compared to HDPE plastic, which is around 0.9 g/cm3. This makes a glass bottle almost three times heavier than a plastic bottle of the same size. In addition, plastic bottles can be made thinner than glass bottles, further reducing their weight.

As an example, we will compare a 2 oz. glass jar and a 2 oz. HDPE plastic jar. Assume both jars have the same dimensions and a 53mm neck opening. A 2 oz. glass jar with a 53mm neck opening will weigh around 82.2 grams. In comparison, a 2 oz. plastic jar weighs only around 13.0 grams. This means it would take 6.3 plastic jars to equal the weight of a single glass jar. This difference is substantial – especially when ordering pallets of bottles in bulk. Based on this analysis, you can see the weight differential impact between plastic and glass on transportation costs and your bottom line.

Understand the Differences

Is glass or plastic better for your product? Only you can determine that. Understanding the differences between glass and plastic will help you make informed packaging decisions. However, if a high priority is reducing your carbon footprint, plastic has distinct advantages over glass.

Is cost management a high priority? Then using plastic packaging may be best. The right material depends on these and many other factors, including packaging safety and the product itself. But plastic has a clear cost advantage over glass.

At Drug Plastics, we invest in our customers’ success and value our partnerships. When you work with us, we provide you with all the information needed to make decisions that improve your sustainability, increase your bottom line, and improve your brand.

Contact Us to Learn More