Contact Us to Select the Perfect Closure Liner for Your Product

Choosing the right type of closure liner for your plastic pill, supplement, vitamin, or lifestyle bottle is one of the most important elements in designing the perfect bottle and closure combination. Not all liners are created equal. It is essential to understand the materials used to make liners and the questions that need to be asked when determining which closure liner is best for your product.

Closure liners are designed specifically for different types of products. Choosing the right liner not only protects your product and the consumer, it can also save you money. Understanding the materials used to make closure liners and the questions to ask when selecting the best liner for your product packaging are essential for determining the correct liner.

Materials Used to Produce Liners

Foam – Various thicknesses of LDPE, PP, EPE, or PS.

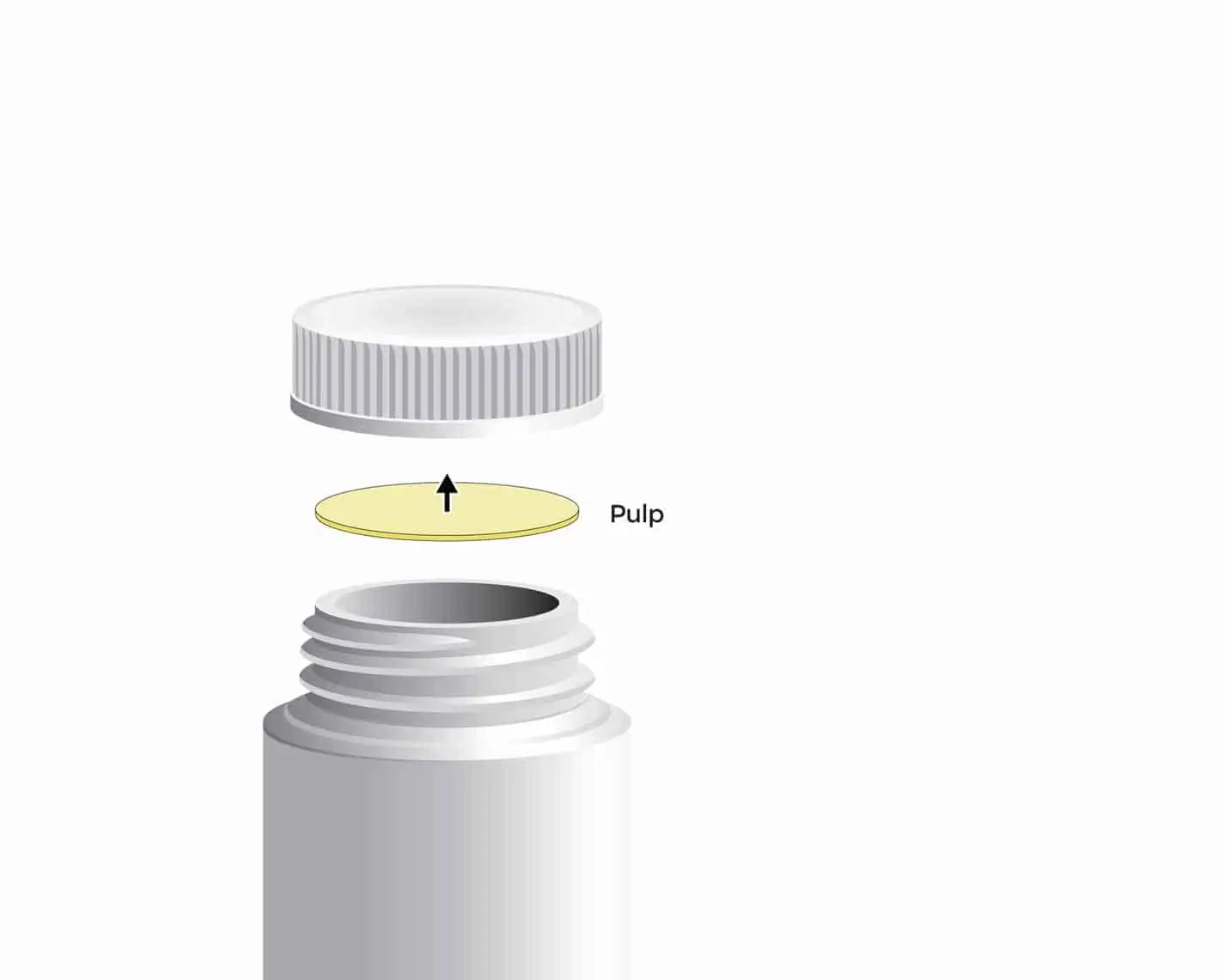

Pulp – Various thicknesses of Cellulose.

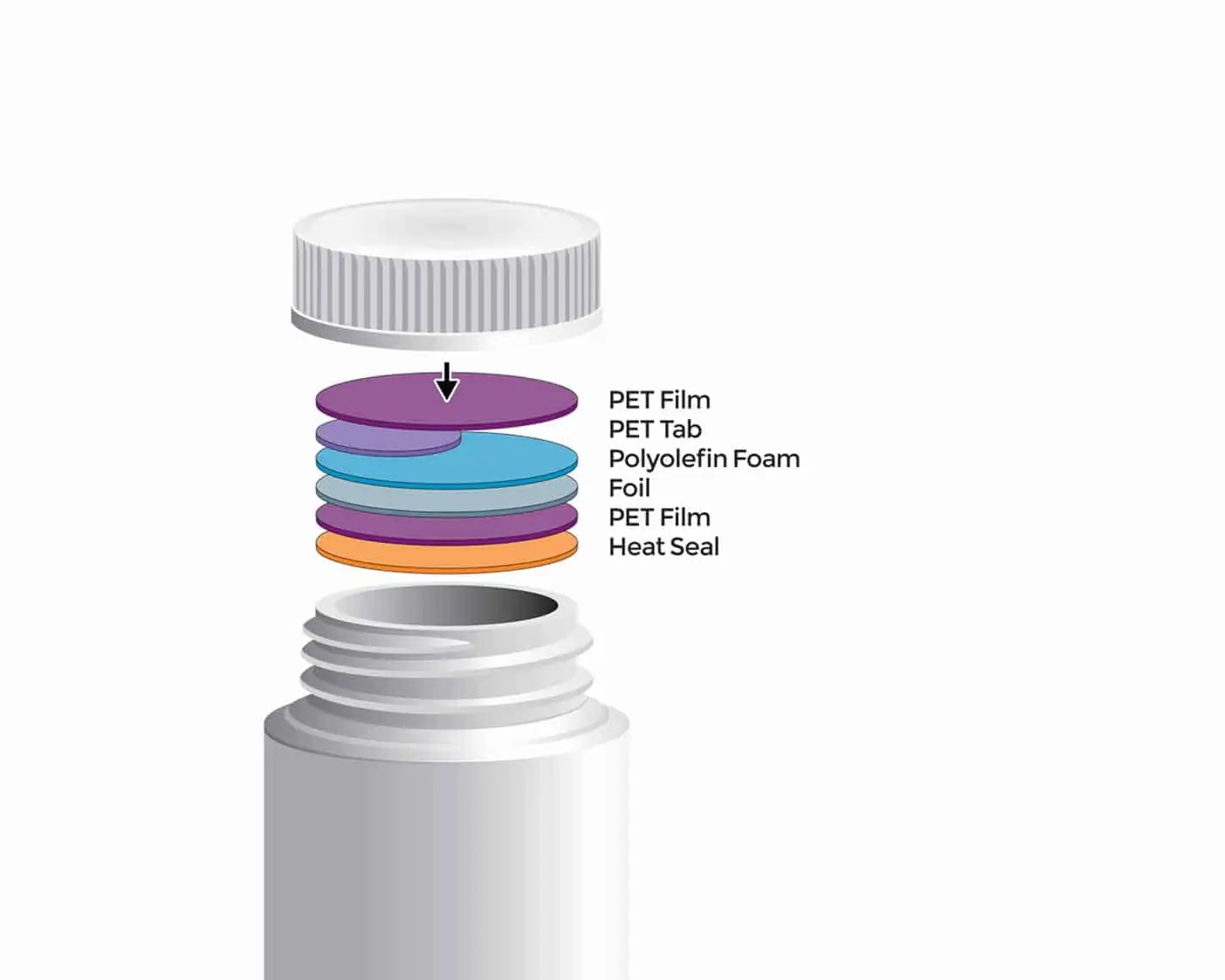

Optional facings – Saran™, PET, and/or foil applied to Foam or Pulp substrates.

Types of Closure Liners

There are 7 main categories of liners.

- Standard Foam Liners

- Standard Pulp Liners

- Modified Foam Liners

- Modified Pulp Liners

- Pressure Sensitive Foam Liners

- One-Piece Induction Seal Liners

- Two-Piece Induction Seal Liners

Questions to Ask When Selecting Liners

- What is the container material type?

- What is the product being packaged?

- What are the product characteristics?

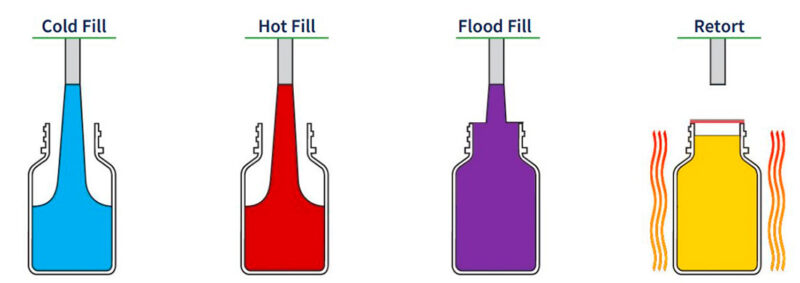

- How will the product be filled?

- How should the liner be removed?

- What is the size of the closure?

- Where are the liner and its materials made?

Save Costs by Choosing Correctly

Picking the wrong closure liner that does not work correctly or is not made for the specific type of contents could damage the product and create lost product, waste, or increased liability for your company. These scenarios add potential costs. In addition, over-specifying the liner means paying more for something that really isn’t needed.

Contact Us to Help You Select the Best Liner for Your Product Packaging