Consumers are increasingly concerned about the environment and conserving natural resources. Companies from all manufacturing sectors are acknowledging this growing concern, and are focusing on how they can reduce their carbon footprint. At Drug Plastics, we are no exception.

That’s why we established manufacturing options, developed tools, and offer suggestions to our customers who feel the same. We want to help our customers create more environmentally friendly plastic packaging.

One of the most impactful ways to create more planet-friendly plastic packaging is by selecting a more sustainable plastic resin. Resin produced through Mechanical Recycling is one option.

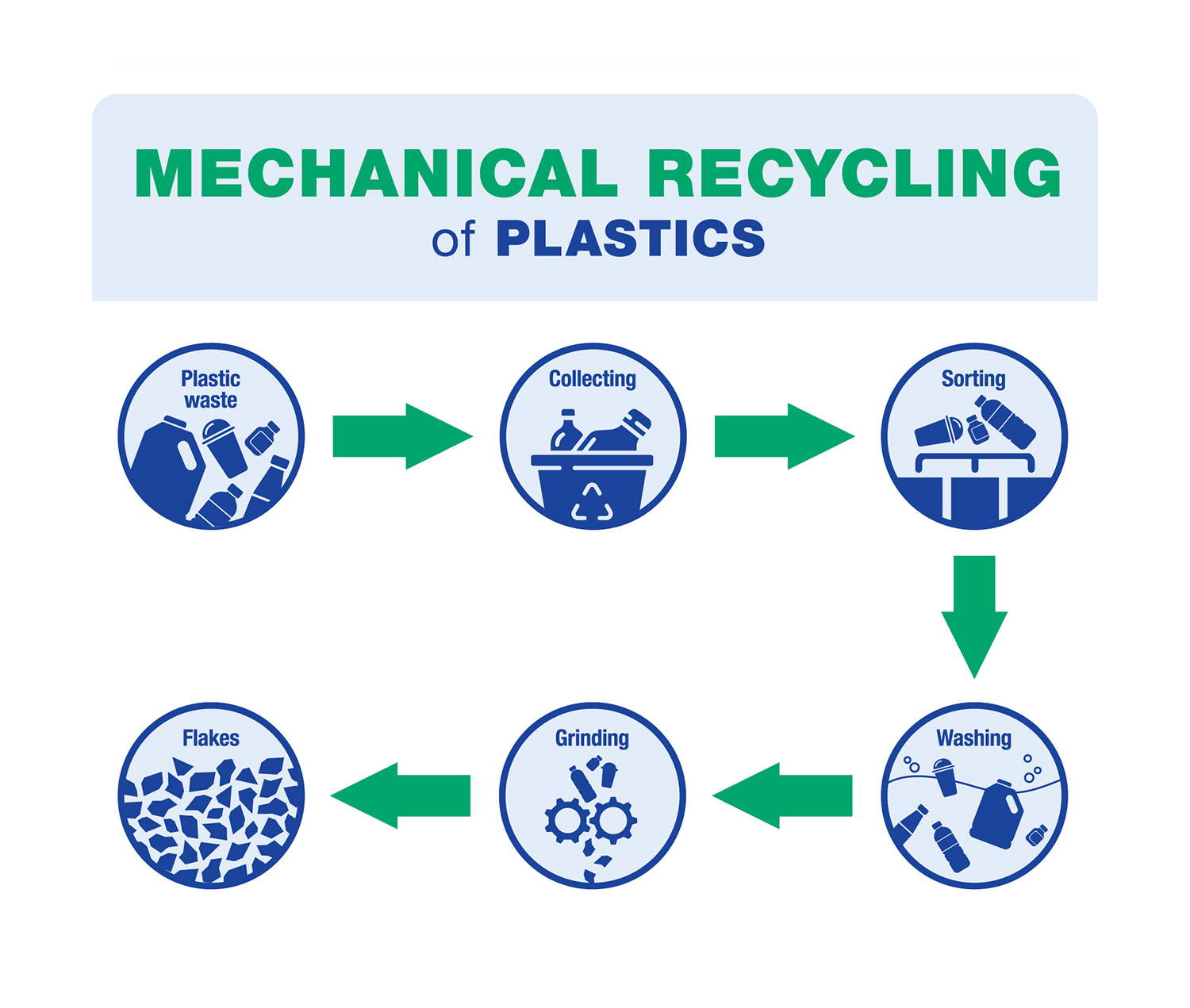

Mechanical Recycling of Plastics

In this process, post-consumer plastic waste is sorted, washed, shredded, and heated back into resin pellets. The actual molecular structure remains intact.

Mechanical Recycling requires raw material that is as clean and pure as possible, and it can only use certain types of plastic waste. In addition, the plastics used can be different colors, so it’s likely that color will vary from batch to batch depending upon the waste plastics’ pigmentation.

Mechanically recycled plastic can only be reprocessed a limited number of times, losing physical properties each time it is processed.

Benefits of Mechanically Recycled Resin

The plastic packaging design process is complex – many decisions must be made, and resin selection is high on the list. There are also notable differences between resin types. Standout benefits of mechanically recycled resin are:

Conserves fossil fuel as a raw material: producing recycled products yields an energy savings.

Reduces carbon footprint: making new plastic products from post-consumer waste is more efficient in terms of greenhouse gas emissions.

Minimizes waste by keeping plastic out of landfills: instead of dumping in a landfill or incinerated, PCR waste is processed and used for other plastic products.

The chart below shows the sustainability benefits of resin produced through Mechanical Recycling, renewable Bio-Materials, and Advanced Recycling. Compare the differences to see which resin is the right choice for your product.

A Manufacturing Partner You Can Trust

At Drug Plastics, our knowledgeable team can guide you through the resin selection process, ensuring that bottles and closures are manufactured with the correct raw materials for the product inside. If you are concerned about sustainability and the impact your business has on the environment, doesn’t it make sense to work with a manufacturer who feels the same? Read our sustainability case study and see how we’re moving forward with our own journey.

We can also explain the sustainable processes, tools, and products in more detail that can help you achieve your goals. Call 610-367-5000 to speak with a knowledgeable representative today.