Easy Ways to Reduce Cost of Plastic Packaging

Buy quality plastic packaging and avoid common defects: Saving money over time.

Uneven Sealing Surface

If the closure seal doesn’t work properly, the integrity of the contents may be compromised, the protection of the child resistant closure may be negated, and your products may be in danger of being recalled. Product waste, lost production time, and replacement of products will eat into profits.

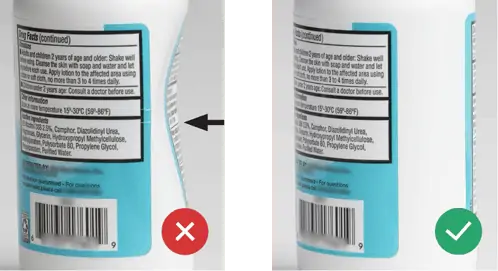

Excess Bottom Flash

Excess bottom flash not be removed from the bottom can cause bottles to not stand straight on the shelf. A poor printing surface and a mediocre brand impression is the result.

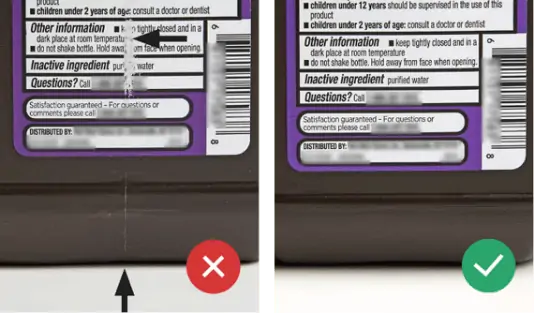

Raised Mold Seams

Raised mold seams on the sides of the bottle result in illegible labels. If the label isn’t legible, consumers can’t find the necessary information they need to make informed purchasing decisions. This can undermine brand loyalty and be detrimental to your bottom line.

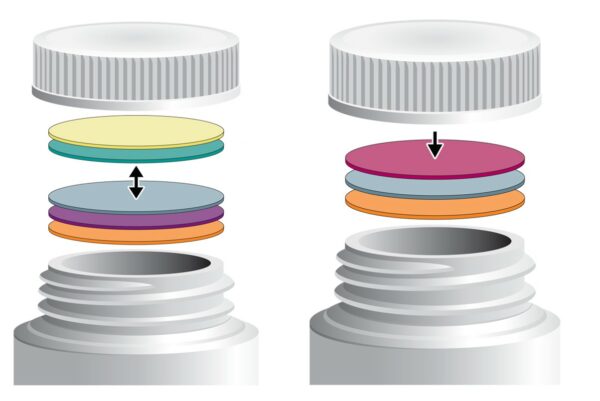

Too Little Plastic or Incorrect Sealing Liners

Causes bottle deformities and problems on filling lines, and after it is filled. We can determine how much plastic is necessary to protect and contain your product. We can recommend the correct sealing liner, avoiding potential issues and save money.

Know the Raw Material Source

Ensure your manufacturer uses materials sourced from and produces their products in the USA. If you select plastic packaging that is manufactured with raw materials sourced from overseas or if the bottles and closures are manufactured overseas, they could have impurities that leach or bleed into your product. In addition, the bottles and closures may not meet regulatory requirements for quality and safety.

We will help you navigate important up-front decisions so you can make choices that save you money.

Use “house” materials instead of “special order” materials. We receive the most competitive pricing for resins, colorants, and other high-volume raw materials that we use regularly. You’ll see savings when you use these standard “house” materials for your orders.

Approval of multiple “like” materials. By approving several resins, colorants, and closure liners frequently used at our production facilities we can avoid the costs for material changes during manufacturing. We can pass these savings on to you through better pricing.

Specify the correct liner. Under-specifying a liner can result in packaging failure and the product can be ruined. When you over-engineer a liner, you will potentially pay more than you need to. Choosing the correct liner avoids unnecessary costs.

Use existing bottle molds. We have molds for hundreds of existing bottle styles that can be used at no additional cost or modified with less cost than designing a custom bottle. There are certain times when a custom bottle is the best solution, but costs will be higher.

Optimize mold cavitation. Custom designed bottles require new molds. The larger the mold, the more expensive the mold. Appropriately sized molds for your projected ordering requirements is important in determining the most cost-effective mold option.

Avoid specialized testing. We manufacture in a cGMP environment and have many standard testing procedures in place. We assure that proper tests are conducted on all resins certifying quality specifications. Requesting redundant tests will add costs.

Use less plastic and save money. Source Reduction is the practice of using less plastic. Depending on the product inside, you may not need as much plastic in the bottle and closure manufacturing process. We’ll work with you to avoid unnecessary costs.

Increase order quantity. Ordering all of your bottles and closures at one time reduces the cost of raw materials since they can be ordered in larger quantities and transported more efficiently. Combining small orders into one large order reduces costs.

Increase order quantity. Ordering all of your bottles and closures at one time reduces the cost of raw materials since they can be ordered in larger quantities and transported more efficiently. Combining small orders into one large order reduces costs.

Increase production run. Reduce cost per unit when your larger quantity bottle and closure orders can be produced at one time. Once the production line is set up and the mold is installed, efficiency is maximized. The longer the machine runs, the more you save.

Reduce collateral shipping materials. Save costs by reducing the type and quantity of shipping materials we use to produce your order. For example, eliminate the twist tie and switch to a fold-over bag inside the shipping carton.

Extend contract length and order commitments. We encourage customers to consolidate their orders for different bottles and closures. This allows us to provide the most competitive pricing based on overall volume. Buying more from us reduces your cost per product.

Speak with your Account Representative or our customer service department at 610-367-5000 to find out more.