As a manufacturer of plastic packaging, we know that packaging’s key function is to keep the product inside protected. Your goal is to provide prescription and self-care medications, supplements, and other lifestyle products safely to consumers. Therefore, it is important to us that the packaging we use protects our bottles and closures during transport to our customers. The packaging has to withstand the rigors of shipping and protect the bottles and closures while they are being stored.

Like many of our customers, sustainability is a high priority for us. We want to ensure that we are reducing our carbon footprint and protecting the environment by using less packaging, while still protecting our bottles or closures. We want to help our customers to do the same.

Reducing costs is an added benefit of reducing the amount of packaging required for an order. We developed the components of our standard packaging with sustainability in mind.

Reducing costs is an added benefit of reducing the amount of packaging required for an order. We developed the components of our standard packaging with sustainability in mind.

Let’s explore how collateral packaging can be reduced, while still protecting the bottles and closures you purchase.

Use One Plastic Bag instead of Two

We package our bottles and closures in poly bags inside cardboard cartons, protecting them from dust and foreign debris. Historically, some of our customers have requested that bottles and closures are double-bagged inside the cartons for reasons that add no value.

We package our bottles and closures in poly bags inside cardboard cartons, protecting them from dust and foreign debris. Historically, some of our customers have requested that bottles and closures are double-bagged inside the cartons for reasons that add no value.

When we eliminate double bagging, it can result in cost savings and a reduction in CO2 emissions. Our Bag Elimination Calculator shows the savings results in everyday examples.

Manage Twist Tie Usage

All types of product packaging use twist ties, like the plastic bags that package grocery items. We also use twist ties to close the poly bags that we use to pack our bottles and closures. Twist ties contribute to waste because they are used once and thrown away. Customers who are concerned with particulate contamination normally use twist ties. Drug Plastics’ method of carton sealing combined with carefully stretch wrapped units reduces this concern. In addition, twist ties are considered strangeware: unexpected and unwanted items that inadvertently end up in a carton of bottles or closures.

Folding the opening of the poly bag instead of using a twist tie will reduce packaging waste. Bottles and closures stored inside folded poly bags, inside a sealed cardboard carton are kept clean while waiting for filling. Read more about proper storage and handling of HDPE bottles, PET bottles, and Polypropylene closures.

Use Standard Size Cartons

We designed our standard carton sizes specifically to fill a pallet. The design was intentional so the optimal amount of space in a full truck would be used. We use IS180 or IS90 cartons for bottles, and IS85 cartons for closures.

We pack our cartons with bottles and closures in two different ways: stack packed or tumble packed. Our experts determine the way a product is packed inside a carton, as well as the carton size used. Most bottles that are 250cc or above 8oz are stack packed inside the carton. Smaller bottles and closures are most often tumble packed.

It is normally more cost-effective to consider our standard packaging for your order. Special carton sizes or packing instructions can incur extra costs for extra materials.

For customers who ship internationally, it was common to use a second outer carton. We have improved our cartons to make them stronger so this can be avoided. If additional protection is required, a more sustainable option to use is corner protectors on the pallets. Corner protectors use less material, which equals less waste.

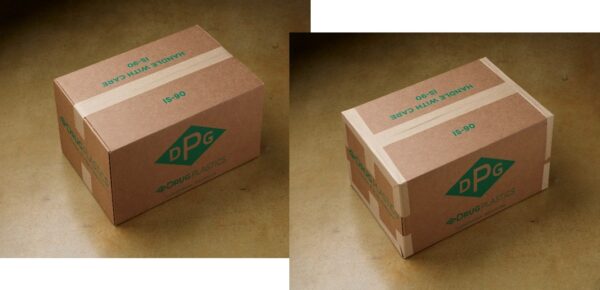

Choose I Tape Configuration

The way shipping cartons are taped can also be changed to increase sustainability. We tape the top and bottom of cartons in either an “I” or “H” tape configuration on bottle orders. Our standard packaging uses the “I” configuration (pictured left), which seals the center seam on the top and bottom of the carton for bottle orders.

An “H” configuration (pictured right) tapes the center seam on the top and bottom, as well as the flap edges on the carton for bottle orders. An “H” tape configuration uses more tape than the “I” configuration. The “I” configuration (pictured left) is adequately secure and uses less tape than the H configuration, so it is easy to make the switch.

A Company that Values the Environment

If sustainability and the health and well-being of our environment is a high priority for you, it make sense to work with a plastic packaging manufacturer who feels the same way. When you work with Drug Plastics, our knowledgeable team will help you explore all of the sustainable packaging choices available for your product. We will also guide you in deciding whether your order should be packaged in standard packaging. Our goal is to help you minimize waste and save costs.

Ready to discuss how we can help? Call 610-367-5000 to speak with a knowledgeable team member immediately.