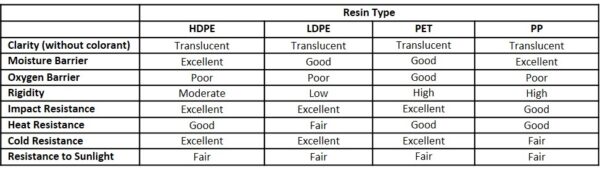

There are a handful of plastic resins used to make bottles and closures. Many bottles and closures are used to package prescription and over-the-counter medications, vitamins and supplements, and lifestyle products. At Drug Plastics, High Density Polyethylene (HDPE); Low Density Polyethylene (LDPE), Polyethylene Terephthalate (PET); and Polypropylene (PP) are used in our manufacturing process. Each different resin type has unique properties which may or may not be the best choice for the product packaged inside.

It’s important to know the characteristics of each resin type when designing and selecting product packaging. But how do you decide which plastic resin is best suited for the bottle used for your product? Our knowledgeable staff can help. Let’s review some of the key characteristics of each resin type.

High Density Polyethylene (HDPE)

HDPE is a thermoplastic polymer that is traditionally made from oil or natural gas. HDPE is one of the most versatile plastics and is used in a variety of applications, like plastic beverage bottles, plastic piping, and of course, plastic bottles for packaging pharmaceutical, nutraceutical, and lifestyle products. HDPE resin is translucent in its natural state; colorants are added during the bottle manufacturing process to change the color.

Bottles made with HDPE resin:

- Clarity: Are translucent and allow some light to pass through, but can achieve light block by adding colorant.

- Moisture Barrier: Have low permeability, meaning it is very effective in protecting products that are sensitive to moisture.

- Oxygen Barrier: Oxygen passes through easily, making it less effective in protecting products that are sensitive to oxygen.

- Rigidity: Moderate at retaining its shape under pressure.

- Impact Resistance: Excellent at avoiding dents and bruises.

- Heat Resistance: Good at withstanding heat up to 145 degrees F.

- Cold Resistance: Excellent at tolerating cold as low as -50 degrees F.

- Resistance to Sunlight: Fair at resisting breakdown from UV light.

Because of these characteristics, HDPE bottles are well-suited for many types of solid dose and liquid medications, vitamin capsules, gel caps, and lifestyle oils, tinctures, gummies, and more.

Low Density Polyethylene (LDPE)

Like traditional HDPE, LDPE is also made from oil and natural gas. Any product that needs to be dispensed by squeezing the bottle is a good candidate for LDPE. Products like lotions, gels, and ophthalmic solutions work well inside LDPE bottles. Although there is very little difference in density between HDPE and LDPE, LDPE has considerably less strength when compared to HDPE.

Bottles made with LDPE resin:

- Clarity: Are translucent and allow some light to pass through, but can achieve light block by adding colorant.

- Moisture Barrier: Have moderate permeability, meaning it is effective in protecting products that are sensitive to moisture.

- Oxygen Barrier: Oxygen passes through easily, making it less effective in protecting products that are sensitive to oxygen.

- Rigidity: Low at retaining its shape under pressure, meaning it is easy to squeeze.

- Impact Resistance: Excellent at avoiding dents and bruises.

- Heat Resistance: Fair at withstanding heat up to 120 degrees F.

- Cold Resistance: Excellent at tolerating cold as low as -94 degrees F.

- Resistance to Sunlight: Fair at resisting breakdown from UV light.

Polyethylene Terephthalate (PET)

PET is part of the polyester family, and is known as the most common thermoplastic polymer resin. PET is commonly used to package liquid dose medications, like cough syrup, as well as vitamins and supplements. It is also a popular choice for lifestyle products in large part because PET can be made in a variety of colors while maintaining its transparent appearance.

Bottles made with PET resin:

- Clarity: Are clear and allow light to pass through, but can achieve light block by adding colorant.

- Moisture Barrier: Have high permeability, meaning it is less effective in protecting products that are sensitive to moisture.

- Oxygen Barrier: Oxygen does not pass through easily, making it a very effective barrier in protecting products that are sensitive to oxygen.

Rigidity: High at retaining its shape under pressure.

Rigidity: High at retaining its shape under pressure.- Impact Resistance: Excellent at avoiding dents and bruises.

- Heat Resistance: Fair at withstanding heat up to 120 degrees F.

- Cold Resistance: Good at tolerating cold as low as -40 degrees F.

- Resistance to Sunlight: Good at resisting breakdown from UV light.

Polypropylene (PP)

Polypropylene is a type of plastic that is known for its semi-crystalline nature. It is a great choice for solid dose prescription and over-the-counter medications, creams and ointments, and powdered supplements. We use PP to manufacture our closures as well.

Bottles made with PP resin:

- Clarity: Are translucent and allow some light to pass through, but can achieve light block by adding colorant.

- Moisture Barrier: Have low permeability, meaning it is very effective at protecting products that are sensitive to moisture.

- Oxygen Barrier: Oxygen passes through easily, making it less effective in protecting products that are sensitive to oxygen.

- Rigidity: High at retaining its shape under pressure.

- Impact Resistance: Good at avoiding dents and bruises.

- Heat Resistance: Good at withstanding heat up to 165 degrees F.

- Cold Resistance: Fair at tolerating cold as low as 30 degrees F.

- Resistance to Sunlight: Fair at resisting breakdown from UV light.

Summary

All of the resins and raw materials Drug Plastics uses are FDA-approved, ASTM-tested, and made in the USA. We never source materials from overseas, providing our customers with the peace-of-mind knowing that their products will pass strict regulatory requirements.

A Trusted Partner for Your Packaging Challenges

Do you have a new product that needs packaging? Do you want to differentiate your brand with new packaging, or do you want to discuss resin options for an existing bottle? Work with us and you have access to over 60 years of manufacturing expertise. Our knowledgeable team can help you determine which type of resin and which bottle will work best for your product.

Our plastic bottles and closures are used all around the world. Put our trusted manufacturing and design experience to work for you and make the right packaging decisions. Speak with someone immediately at 610-367-5000.