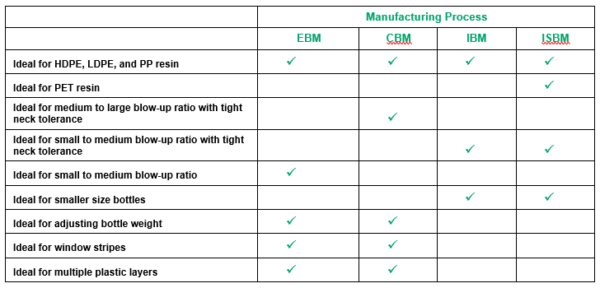

Which Blow Molding Process is Right for Your Bottle?

Extrusion Blow Molding

The EBM process is used to manufacture large-size, High Density Polyethylene (HDPE), Low Density Polyethylene (LDPE), and Polypropylene (PP) bottles with large necks.

Compression Blow Molding

The CBM process is used to manufacture bottles that have large bodies and relatively small necks. The bottles can be made with HDPE, LDPE, and PP resin, and can achieve very tight critical neck dimensions.

Injection Blow Molding

IBM is ideal for the production of HDPE, LDPE, and PP bottles that have small bodies and relatively small necks. IBM is used when manufacturing bottles with very tight neck tolerances.

Injection Stretch Blow Molding

ISBM is used to manufacture bottles that have small to medium bodies and relatively small necks. We use ISBM to manufacture all of our Polyethylene Terephthalate (PET) bottles.

Summary

Speak with a knowledgeable team member for further details on our manufacturing processes at 610-367-5000.