When it comes to plastic bottles, style choices are endless. Should you use a round bottle or a square bottle?…

How the Bottle Neck affects Product Dispensing

Living Our Mission

Drug Plastics believes that pharmaceutical, nutraceutical, and lifestyle product packaging should be functional, easy to use, safe, and have repeatable…

How Source Reduction Benefits Plastic Packaging

Source Reduction, also known as Right-Weighting, is the practice of reducing the amount of plastic resin used to manufacture bottles…

Increase the Shelf Presence of Your Brand

Plastic bottles and closures are available in many shapes, sizes, and colors. Protecting the contents inside, ease of use, and…

Virgin Resin or Recycled Resin: How to Choose

Plastic resin derived from fossil fuels is used to manufacture all types of plastics – including plastic bottles and closures…

How to Make Pharmaceutical Packaging More Sustainable

One of the most widely used bottles and closures for pharmaceutical packaging is a Wide Mouth Pharmaceutical Round Bottle and…

Customize Plastic Packaging to Make it Your Own

Drug Plastics can help you design and produce the perfect plastic packaging that reinforces your brand. When a stock plastic…

Why Won’t My Bottle Work with a SecuRx® CR Closure?

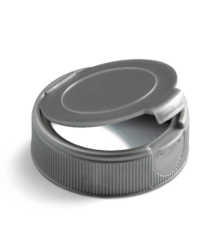

At Drug Plastics, we manufacture many types of plastic closures for our bottles: continuous thread, snap cap, dispensing top, as…

Understanding Tamper Evident versus Child Resistant Packaging

Creating product packaging is quite complex. There are many types of packaging – from plastic bottles and closures, plastic bags…

Why the Shape of your Plastic Packaging Matters

A plastic bottle is a plastic bottle, right? Well, not really. The shape of a bottle is an important factor…