At Drug Plastics, we are committed to sustainable solutions for our customers. Our Sustainability Calculators were developed to help you learn more about how simple changes can impact the carbon footprint of our planet. We invite you to explore these tools and join us in our efforts to become more sustainable and help save the environment for generations to come.

Call us at 610-367-5000 for Product Assistance

Cut Greenhouse Gases with Post-Consumer Recycled (PCR) PET

You can help decrease greenhouse gas emissions levels that are damaging our planet by changing to PCR plastic packaging. Making new products from PCR PET removes plastic from the environment by converting PET plastic discarded by the consumer back into resin that can be used again.

Eliminate Flame Treatment

An easy way to conserve fossil fuels like natural gas is to opt out of the flame treatment process. Historically, the use of flaming in the plastic bottle manufacturing process ensured that water-based adhesive labels and silk screening would adhere properly to HDPE, LDPE, and PP bottles. Today, this is not always necessary, depending on the label type you are using.*

*We recommend consulting with your label provider.

Use One Bag Instead of Two Inside the Shipping Carton

Reducing the amount of collateral packaging we use helps us reduce our carbon footprint. In addition, we strive to find solutions for our customers to do the same. Our Bag Reduction Calculator will help you determine the individual savings when you move from double bagging to single bagging bottles and closures inside the carton.

Switch to Natural Resin and Save CO2 Emissions

Titanium dioxide concentrate is a white pigment that is added to natural plastic resin to give a bottle a white color. Have you considered switching from a white pigmented bottle to a natural bottle without pigment? Switching from white pigmented bottles to those made from resin in its natural color state can make a big difference in carbon dioxide emissions. Use our Concentrate Elimination Calculator to see how many tons you can eliminate.

Convert from Glass to PET Plastic and Conserve Natural Resources

PET requires less energy to produce than glass, saving natural resources. It is also lighter than glass, reducing the cost and the amount of fuel required for transportation. Try out our Glass to PET Conversion Calculator on a typical order and see how choosing PET can help improve your carbon footprint and reduce your costs. Then, use our Post-Consumer Recycled (PCR) PET Sustainability Calculator and see how you can save even more.

Realize Savings by Switching from Glass to HDPE Plastic

Glass and plastic comprise most bottles and jars used for product packaging. Plastic is well-known for having some significant advantages for the consumer when used instead of glass for packaging – especially relating to sustainability. Our Glass to HDPE Conversion Sustainability Calculator provides an in-depth analysis into sustainability to help you make a more informed choice about whether to utilize glass or plastic as your packaging material.

Reduce Your Carbon Footprint with Post-Consumer Recycled (PCR) HDPE

Reduce your company’s carbon footprint by switching to PCR HDPE. Making new bottles from PCR HDPE eliminates plastic from the environment by converting HDPE plastic that is thrown away by consumers back into resin that can be used over and over to make new products.

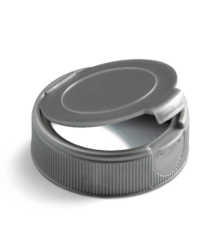

Switch to Child Resistant Closures that Use Less Plastic

There are many types of child resistant closures on the market. When you choose a closure that uses less plastic, you take a positive step towards conserving natural resources. For instance, switching to a single wall, one-part closure – such as our Snap Cap or Pop & Click™ from a double wall, two-part closure, like our SecuRx® closure – can save on carbon dioxide emissions during production, while still maintaining application versatility, FDA-approval, and passing child resistant safety regulations.*

*Calculator is based on resin reduction only.